Master, the largest manufacturer of brake systems for trucks, buses, trailers, and semis in South America presents a series of new solutions in line with some of the most important market demands at Fenatran 2019. Our line of Piston-type brake chambers VHO, Disc brake chambers, and innovative products such as CP 410 Brakes and ELSA Disc Brakes, models 225H and 225E, will be highlighted at the event. As well as those new products, Master presents a complete line of pneumatic actuator systems for trucks, buses, and semis. “Master products combine high-tech and competitive costs to offer top braking performance and safety for our clients”, says company CEO Ricardo Escoboza.

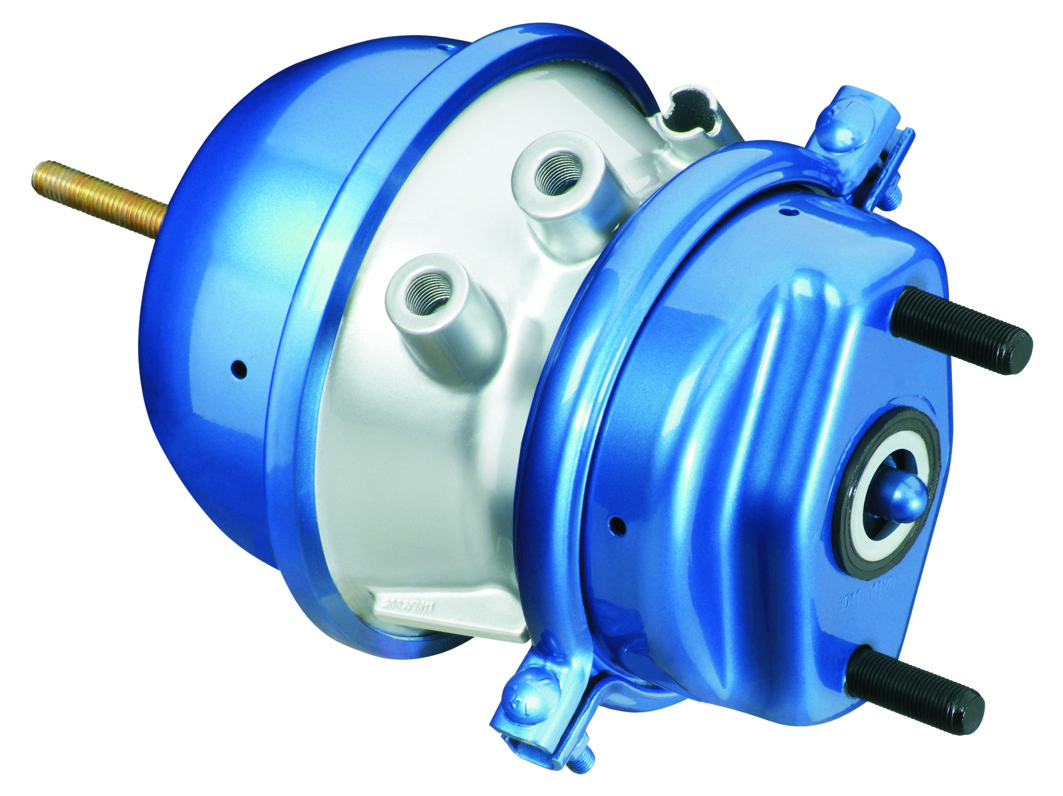

One of the products highlighted at the event are the new piston-type chambers VHO, which have an increased 54% actuation power for parking. Compared to previous models, these new products guarantee more safety and durability than double diaphragm chambers, as they apply the concept of a piston to the parking compartment. Robust, durable, and with high starting power from parking, the product was developed to meet Contran regulations, as well as requirements from all assemblies for use in heavy and extra-heavy vehicles.

The new VHO line uses external breathers as a standard and supports internal breathers with a valve for use in highly contaminated environments. Furthermore, the innovative internal corkscrew system used to retract springs guarantees they can be installed in positions in which an external system cannot be used. Closure of the parking compartment is done via socketing, guaranteeing excellent sealing. As well as VHO piston-type chambers, Master also presents its line of chambers for use with disc brakes.

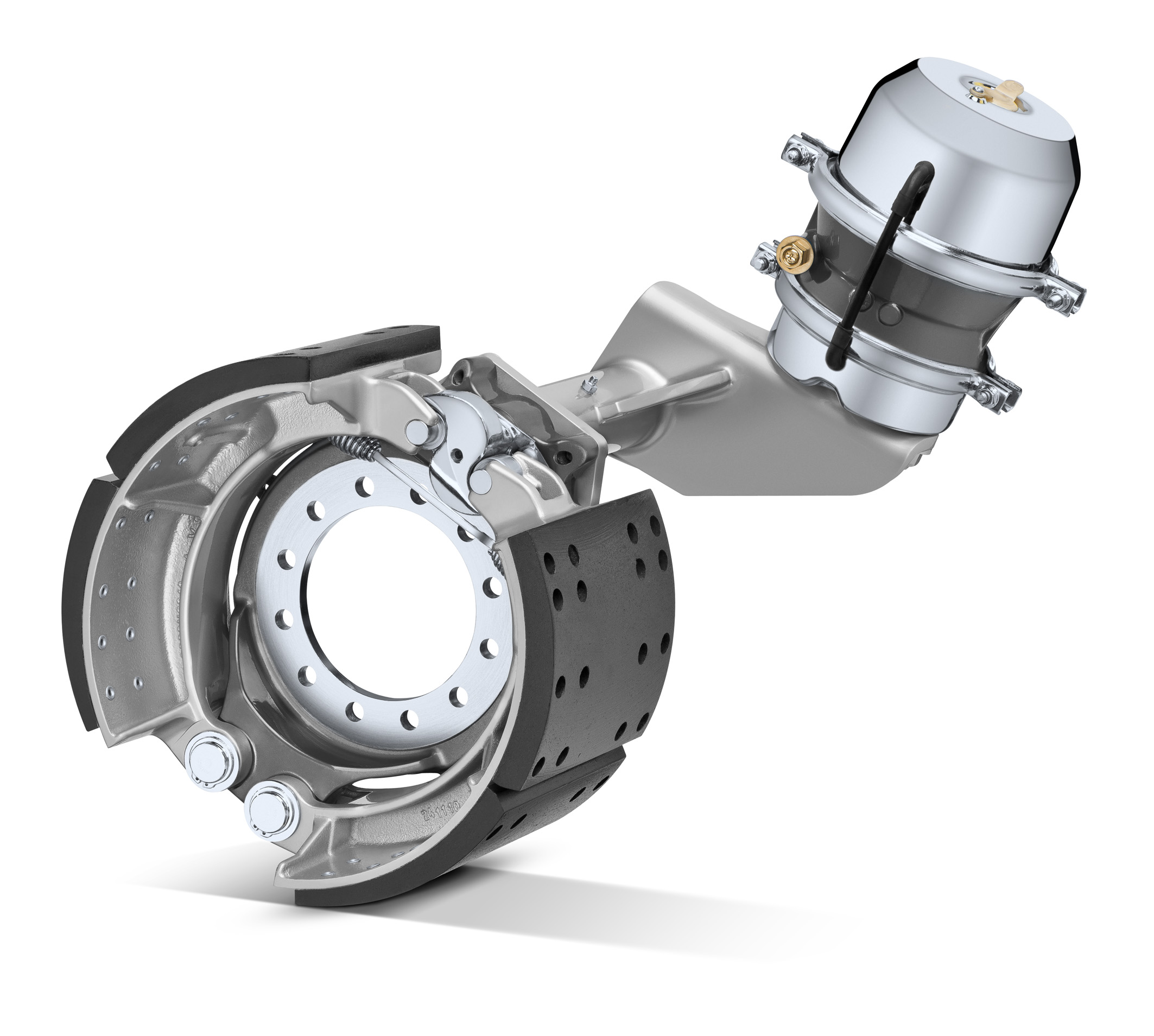

CP 410 Brake includes several innovations fit for a premium product by Master. It was developed for the most severe uses throughout markets around the world, regarding both road conditions and load capacity. Designed for use in heavy and extra-heavy vehicles, the new brake system has shown exceptional performance on the field. It offers high torque and superior durability, resulting in excellent gains for the freight company regarding safety and operation costs.

Brake geometry design optimization led to volume gains in friction material. Consequently, this has increased the time between maintenance downtimes and reduced costs for freight companies. Shoes are fused to increase braking system rigidity, improving heat transfer during braking. Among other features that make it stand out, CP 410 Brake also includes highly effective seals, guaranteeing more efficient lubrication. It may be interchangeable with similar systems (on demand) and braking support is highly rigid, which decreases actuator spending and increases the useful life of the system.

Master also presents its ELSA Disc Brake line, models 225E and 225H. These products meet all demands from freight companies in Brazil and around the world. Friction material on those new products is extra thick. They also include automatic adjusters. They may be equipped with a service chamber or with spring brake chambers. They also feature stainless steel wear strips with double sealing, double pad activators and an optimized friction area to give pads and rotors maximum durability. Alongside our new products, Master will also display pneumatic system parts such as pneumatic brake system valves and products for air supply systems in pneumatic brakes.

Photos: Jefferson Bernardes and Panda Branding