South America’s market leader in Suspension and Axle Systems and in Wheel End Systems for implements, trucks, and buses, Suspensys introduces to the cargo transportation market a solution for energy optimization of disruptive contours: the e-Sys traction module. It is developed by the company itself, in consolidation with one of the sector’s most groundbreaking companies in Brazil, tested at the state of the art Randon Technological Center (CTR). The concept utilizes the auxiliary system of energy recuperation generated during breaking and descents, enabling the trailer to help the horse to go uphill in a manner that is safer and more efficient. Depending on the application, loading conditions, and the road, the fuel savings can reach up to 25%, also providing less component wear and less waste emission into the environment.

The storage and electric regeneration technology is a first in Latin America and was inspired by Formula 1, which utilizes the KERS (Kinetic Energy Recovery Systems) System. After two years of development together with the respective areas of engineering, laboratories, and testing grounds, when it enters into commercial scale, it will also be available to the national and international market of equipment for cargo transportation.

“e-Sys is another example of Randon Companies technological leadership. This innovation reduces the so called TCO (Total Cost of Ownership) with energy consumption savings and less time on trips. At the same time it increases safety, with the addition of the break regeneration system. And it also presents green, renewable technology, therefore it is friendlier to the environment”, states the vice president and COO of the Randon Companies Auto Parts Division, Sérgio L. Carvalho. The application in road train trucks and the Brazilian rugged continental topography make this system an attractive proposition for a wide range of fleet owners, explains the businessman.

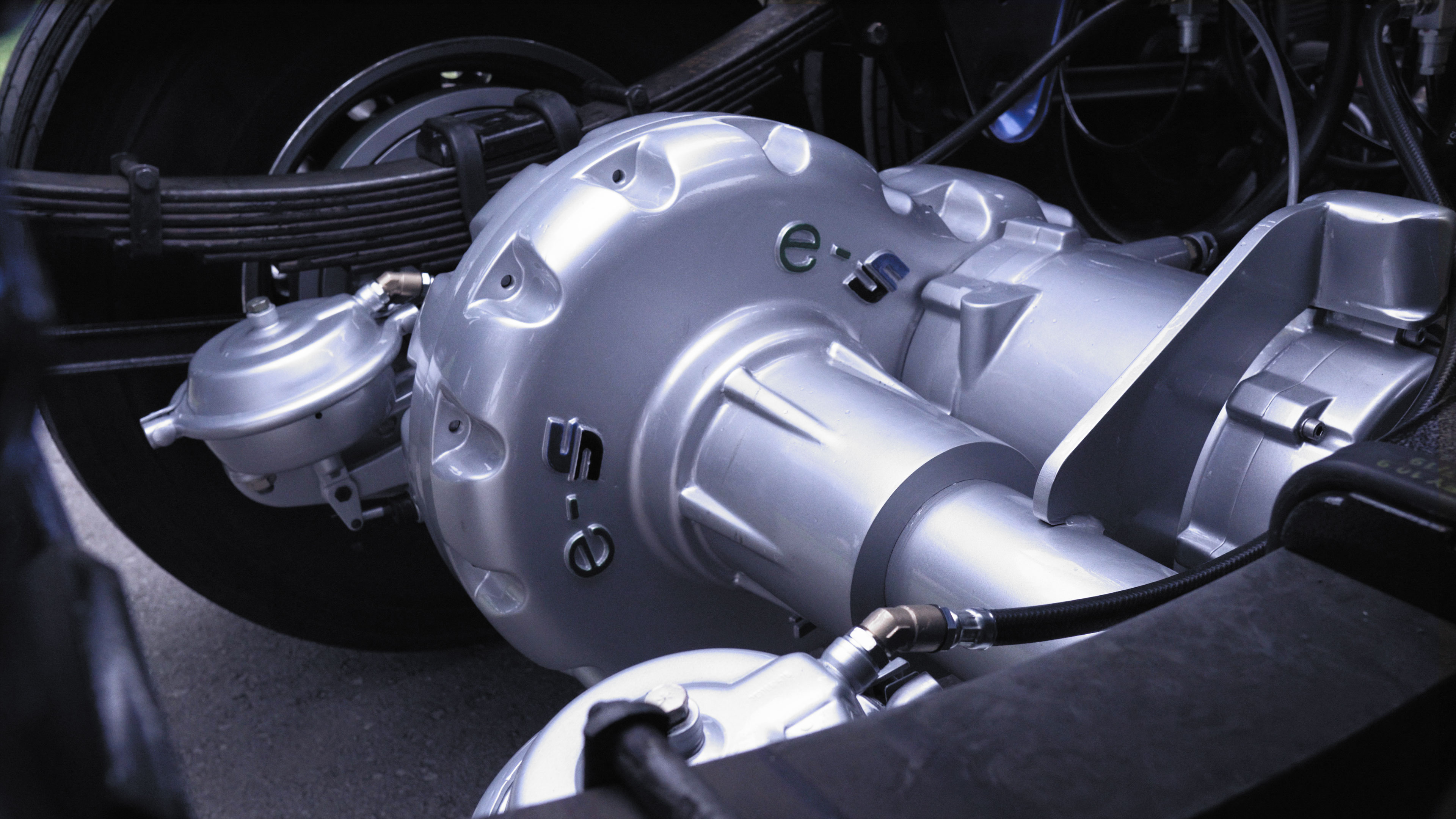

“The e-Sys system operates from an electromechanical set formed by an Electronic Control Unit (ECU), battery, switch and WEG electric engine coupled to an axle developed exclusively for this purpose”, says Sérgio Carvalho.

To promote savings, the components are managed by an intelligent algorithm specially developed to evaluate use and operational conditions, allowing the implement to relieve the horse’s effort in certain conditions, such as ascents. “The algorithm was specially developed by Suspensys, with the support of partners, to maximize fuel reduction and, above all, guarantee maximum set security”, highlights Suspensys director, Esdânio Pereira.

According to the director of Innovation and Technology of the Randon Companies Auto Parts Division and director of the Randon Technological Center (CTR), Cesar Augusto Ferreira, the engine starts to work as a generator, recuperating kinetic energy and storing it in batteries that will feed its own trailer’s electric engine. “The diverse characteristics of the Brazilian terrain, with its irregularities in continental scale, associated to our loading conditions and weight-power ratio, besides the legislations on cargo and coupling, they are constituted in an ideal scenario for utilizing the e-Sys system, which arrives to accelerate the energetic optimization of the cargo and vehicle set.

Photo: Felipe Fedrizzi/Tazum